ND Microspheres® Acrylic

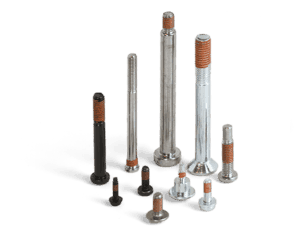

ND Microspheres Acrylic is a process in which microencapsulated, room temperature curing acrylic threadlocking adhesives are applied to male or female threaded fasteners of virtually all sizes, materials and finishes. Acrylic threadlockers offer consistent and predictable torque values and require no heat or primers for curing.

[st_tag_cloud]

How it Works

After choosing ND Microspheres Acrylic processing, have your parts sent to one of ND’s service centers. ND will then apply a microencapsulated activator suspended in a quick curing waterborne resin. This material dries on the part and is then shipped back to the customer for use. When installed, the shearing forces caused by engagement with a mating part release the activator and allow it to mix with the resin. The resulting chemical reaction rapidly bonds the surfaces, locking the parts together and sealing leak paths.

Chemical Resistant

Processed parts resist and seal against most automotive fluids. Oil, water, antifreeze, and gasoline have virtually no effect on performance once the final cure has been achieved.

Versatile

ND Microspheres Acrylic processing can be specified in a variety of colors for easy part inspection and in different strengths to fit the desired application.

High Temp & Torque Sensitive

ND applies material formulations which are specifically intended for use in high temperature or torque/tension sensitive applications.

Fast Fixture Times

After installation parts typically fixture in under 5 minutes. However to reach full strength it is recommended to allow a full cure of 72 hours.

Color Identification

ND Microspheres Acrylic processing is available with a variety of colors for easy part inspection and in different strengths to fit the desired application.

Surpasses IFI Standards

ND Microspheres Acrylic procesed parts meet or exceed all torque requirements of IFI 125, IFI 525, as well as automotive adhesive coated fastener performance specifications.