Thermoseal™

Thermoseal™ 400 is an ND pre-applied process in which a hybrid microencapsulated high-pressure sealant with medium strength threadlocking capabilities is applied to fasteners. Thermoseal self-locking and self-sealing fasteners are able to meet the demands of high temperature, high pressure applications where other thread sealing materials would fail. Thermoseal processing may also provide a lower coefficient of friction than other thread sealants to help with ease of installation.

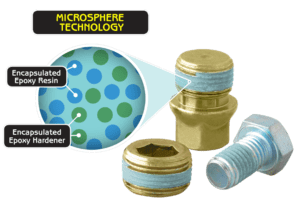

How it Works

Thermoseal processing involves the application of two-part, dual-encapsulated dry film adhesives to male or female fasteners. Upon installation with a mating part, shear forces cause the microsphere capsules to rupture, mixing the two components, initializing the reaction and curing to form a strong chemical bond and effective seal.

Thermoseal 400 processing creates a fastener with exceptional sealing properties and the ability to withstand pressures up to 40MPa. In addition, it prevents loosening due to vibration, shock, and thermal effects. Thermoseal fasteners can replace the need for PTFE tape due to its better reproducibility and speed of installation.

Versatile Application

Thermoseal pre-applied fasteners provide excellent protection from pressure, heat and loosening due to vibration, shock, and thermal effects. Thermoseal processing creates both a self-locking and self-sealing fastener through its reactive curing technology.

High Pressure Seal

Thermoseal processed fasteners are able to withstand high sealing pressures with burst pressure in excess of 5800 psi (40MPa) under challenging conditions.

Chemical Resistant

Upon installation, the adhesive in Thermoseal fasteners create a cross-linked molecular structure making it one of the most resistant types of adhesives. Oil, gasoline, salt spray, acids, solvents, and water have virtually no effect on parts when introduced after final cure.

Surface Insensitive

Thermoseal processing is compatible with most fastener sizes, configurations, materials and finishes. The use of an epoxy based microsphere adhesive ensures that a strong reliable lock and seal are formed.

Secure Lock

Once cured, a medium strength lock is formed which helps prevent loosening under vibration or reversal of stress and greatly reduces the need to re-tighten fasteners.

Long Shelf Life

Thermoseal processed fasteners have an on-part life of 1 year and will remain inert until a cure is activated by engagement with a mating thread.