OVERVIEW

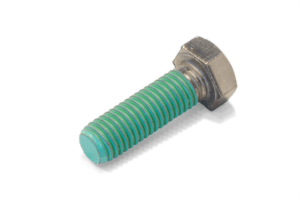

Thread Armor® VC is a pre-applied thread lubricating coating process which contains a PTFE material for anti-galling on Stainless Steel fasteners. Cross-linking within the coating provides excellent solvent resistance, high temperature resistance, e-coat resistance, weld spatter resistance, resistance to most typically used automotive fluids, and improvement to torque-tension properties.

HOW IT WORKS

After choosing Thread Armor® VC processing, have your parts sent to one of ND’s service centers. ND will then apply the appropriate materials to your fasteners with our automated equipment which ensures consistent, quality results. Coated fasteners are then dried and repacked as needed. Upon arrival, parts are ready for immediate installation and use.

Reliable Masking

Thread Armor VC prevents undesirable substances such as electro-deposited undercoatings, weld spatter and some other materials from adhering to fastener threads.

Low Heat Process

Unlike competitive processes which often subject parts to extremely high temperatures that may damage or discolor the fastener, ND’s unique patented process employs minimal heat.

Minimal Pre-Cleaning

Unlike competitive processes that require parts be completely free of oil or other rust preventative coatings, only parts with excessive oil or surface contaminants may require pre-cleaning.

Eliminates Capping & Plugging

Thread Armor VC eliminates the need to cap male and plug female threads.

Increases Productivity

Increases efficency by lubricating fastener threads which reduces driving friction, heat buildup, and thread galling in long rundowns while helping to ensure uniform clamp loading.

Versatile Application

Thread Armor VC processing creates a cross-linked coating which provides excellent solvent resistance, high temperature resistance, e-coat resistance, resistance to weld spatter, and improvement to torque-tension properties.