Pre-Applied Vibra-Tite® VC-3®

Pre-Applied Vibra-Tite VC-3 is a process in which customer fasteners are coated in bulk with VC-3 Threadlocker. Vibra-Tite VC-3 is a proprietary blend of thermoplastic elastomer resins which exhibit excellent adhesion to all fastener finishes along with high resiliency behavior. The combination of inert/non-reactive amorphous resins creates a tough, semi solid layer inside the threads of a mated joint. Similar to rubber engine mounts, Vibra-Tite VC-3 damps/disrupts the vibrational energy transferred between the threads of a mated fastener, preventing fastener loosening and loss of clamp load. Finally, the malleable nature of the resins allows it to be reused up to five times, making joint assemblies utilizing Vibra-Tite VC-3 serviceable and/or adjustable when necessary.

How it Works

Fasteners sent to ND Industries, undergo the Pre-Applied Vibra-Tite VC-3 process in which VC-3 is flow coated onto internal or external fastener threads made of virtually any material or finish. Unlike many other pre-applied threadlockers, VC-3 processing does not require heat which reduces the chance of degradation of the fastener or its finish. Parts arrive to the customer dry to the touch and ready for installation.

Versatile

Processing is compatible with both ferrous and non-ferrous metals, most platings, wood, and nylon, PPE, or PP plastics. There are no limitiations on fasteners size or configuration.

Excellent Shelf Life

When in a cool and dry environment, Vibra-tite VC-3 processed parts can be stored indefinitely before use.

Reliable & Powerful Lock

With exceptional reliability, VC-3 holds parts in place even during extreme vibration and resists leakage by acting as a dam between mated threads.

Reusable

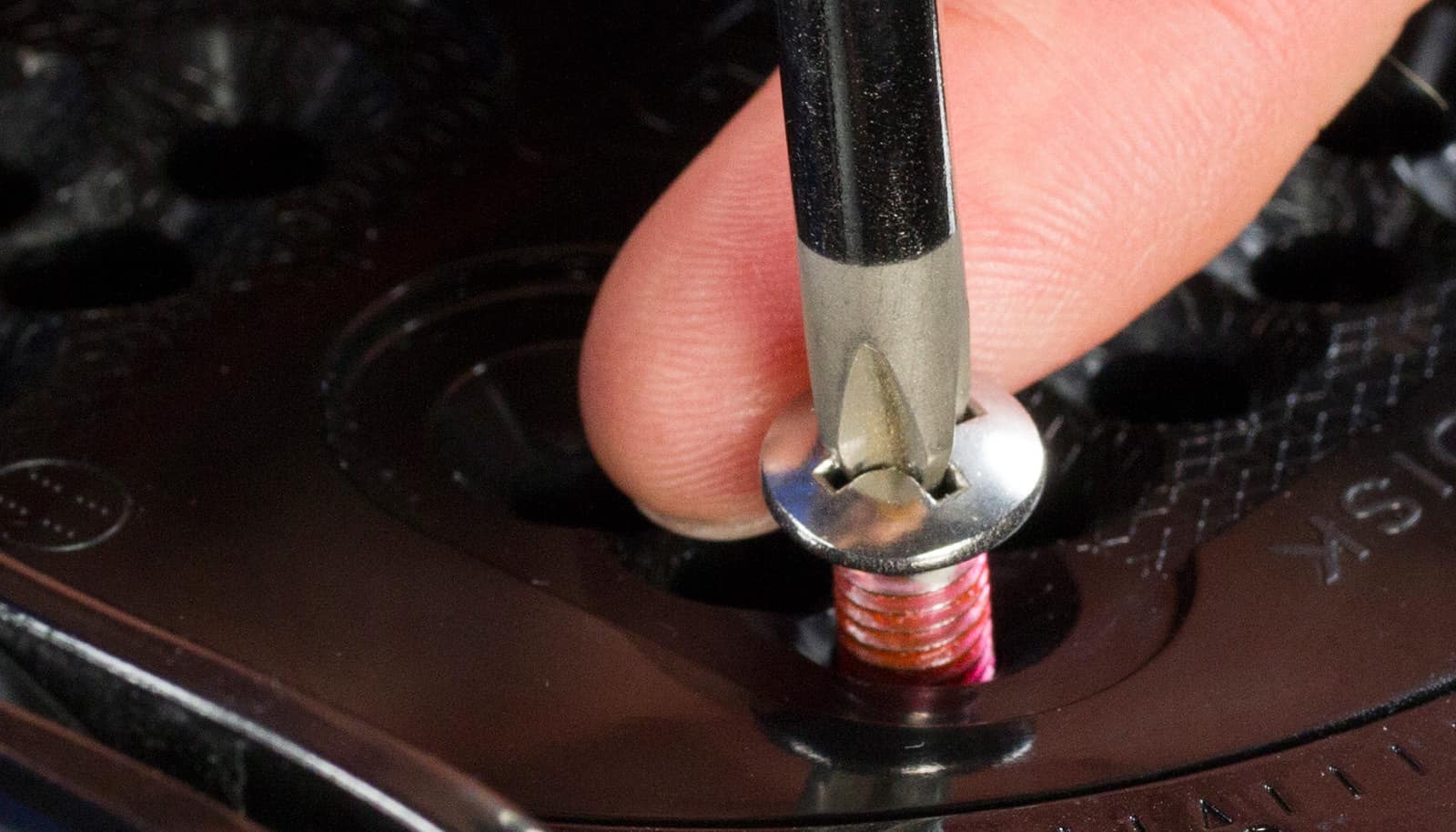

Using steady pressure and standard hand tools, Vibra-tite VC-3 parts can easily be adjusted, removed, and reused.

Minimizes Galling / Stripping

Since Vibra-tite VC-3 remains a thick, resilient, cold flow resin, its properties actually minimize galling or stripping of soft threads during reuse.

Chemical Resistance

Resistant to most solvents (acts as a partial corrosion barrier) with total resistance to water and salt water.