ND Plastisol

ND Plastisol processing involves the application of closed cell PVC materials directly to fasteners, washers, and other parts for a variety of purposes. ND Plastisol is used extensively in the automotive industry and adheres to many substrates.

How it Works

During the pre-application process, ND Industries precisely dispenses liquid plastisol PVC onto parts and then heat cures the material in place. The resulting product is dry to the touch and ready for immediate installation. Plastisol can be applied to a wide variety of parts for use in functions such as: • Cushioning • Insulating • Masking • Sealing • Trimming • Controlling Noise • Reducing Vibration

Advanced Sealing

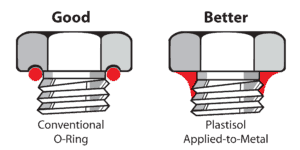

ND Plastisol provides an immediate positive seal that eliminates leaks and fills voids between mating parts.

Versatile

ND Plastisol processing is compatible with ferrous and non-ferrous metals including a wide range of common fastener finishes.PVC plastisol has a functional temperature range of -40°F to 320°F.

Reliable

Unlike O-rings and nylon washers which are difficult to seat, tear easily and lose integrity when nicked or cut, ND Plastisol processed fasteners are easy to seat and perform consistently.

Environmental Resistant

ND Plastisol offers weatherability and dielectric strength while providing excellent chemical, abrasion, UV, and ozone resistance.

Custom Formulas

ND Plastisol processing is available in virtually any durometer (hard to soft), and in any color, including fluorescent and clear.

Long Shelf Life

ND Plastisol processed parts exhibit an extended shelf life and will not dry or shrink with exposure to the environment.