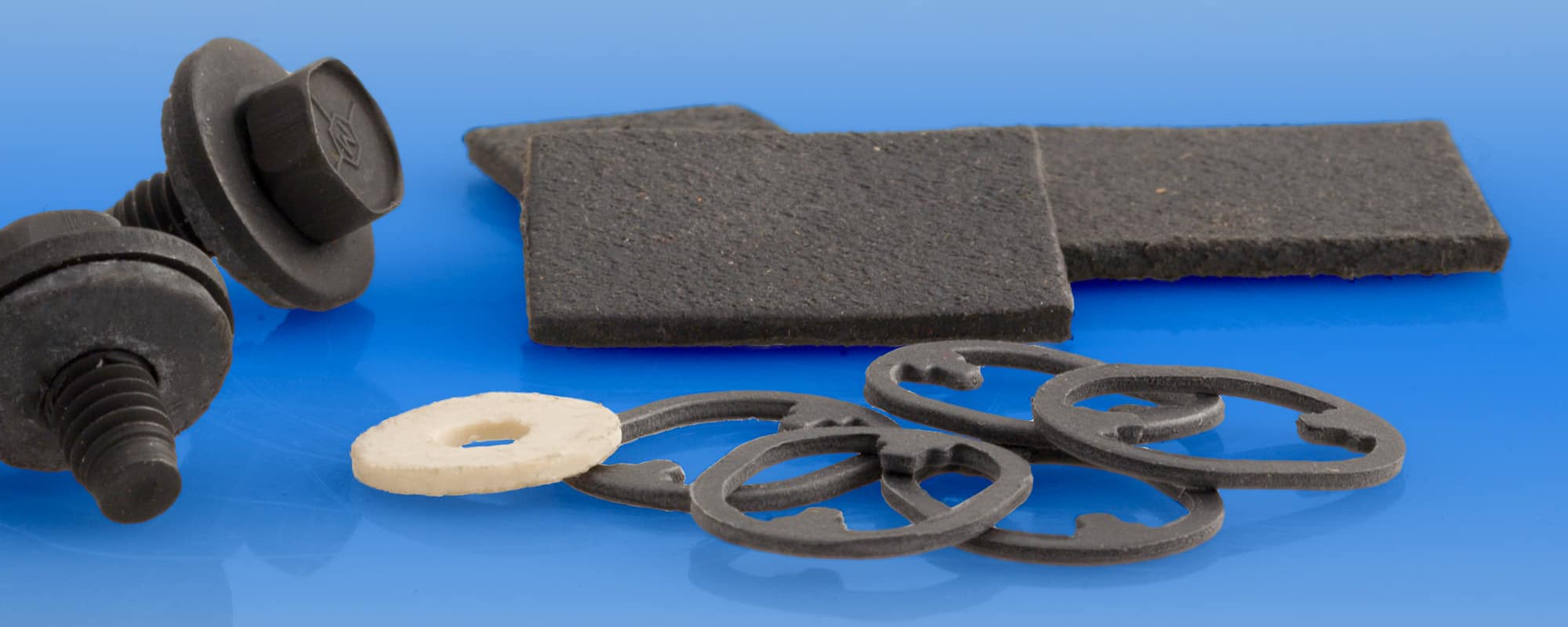

ND Expandable Mastics

ND Industries’ heat expandable mastic products are used in a wide variety of applications providing economical solutions for the prevention of metal-to-metal contact, vibration, and noise-related problems (sometimes referred to as flutter). An excellent anti-flutter compound, ND Expandable Mastics are an extruded product made in standard, custom, or complex die cut shapes and thicknesses to meet customer requirements for sealing, noise dampening, and vibration reduction.

How it Works

ND Expandable Mastic extrusions are ready-to-use in an uncured form and can be applied or bonded to any metal surface prior to the application of heat. When heat is applied, generally in a primer oven, a reaction takes place that causes the material to expand and adhere to the metal surfaces and create a seal while filling all space between the metals. Our product offers expansion rates ranging from 100% to 700%. The material is stable, non-volatile, resistant to most chemicals, has a long shelf-life, and is compatible with production phosphatizing and paint systems.

Suppress flutter & vibration

When used as backing for sheet metal panels, it prevents flutter, seals, reduces vibration, and deadens sound.

Bonding

ND Expandable Mastics will provide some metal-to-metal bonding once it is fully cured.

Volume filler

ND Expandable Mastics swell to fill the cavity it is placed in. Between two layers of sheet metal, the material acts as an insulator from moisture, air, dust, and noise.

Sealing

In a cured or uncured state, ND Expandable Mastics secure the intended area from penetration by moisture, gases, dust, sound, and vibration.

Adhesion

ND Expandable Mastics offer excellent adhesion to metal substrates - without additional adhesives or tape.

Standard Profiles

ND Expandable Mastics are available in a variety of lengths and diameters to provide a quick and flexible response to a customer's need.